With the revisions to the Lead and Copper Rule under the National Primary Drinking Water Regulations of the Safe Drinking Water Act tightening requirements on lead in drinking water, awareness and attention of lead and copper corrosion is on the rise. Additionally, increasingly stringent water quality regulations have utilities increasing their reliance on membrane technology. As a result, and to better serve our utility clients, Globaltech performs lead and copper corrosion control bench-scale studies to address these new requirements.

We recently provided these beneficial studies for Fort Pierce Utilities Authority (FPUA) at the Henry A. Gahn Water Treatment Plant (WTP). The WTP utilizes both low-pressure reverse osmosis (LPRO) membrane technology and conventional lime softening (LS), blending the two treated process waters for potable water production. In proactive fashion, FPUA began reviewing options to increase the use of its LPRO process, projecting higher blend ratios of LPRO to LS process water. To aid FPUA in future planning, Globaltech performed a bench-scale lead and copper corrosion study that evaluated several LPRO/LS process blends and several corrosion inhibitor formulations for relative lead and copper corrosion potential.

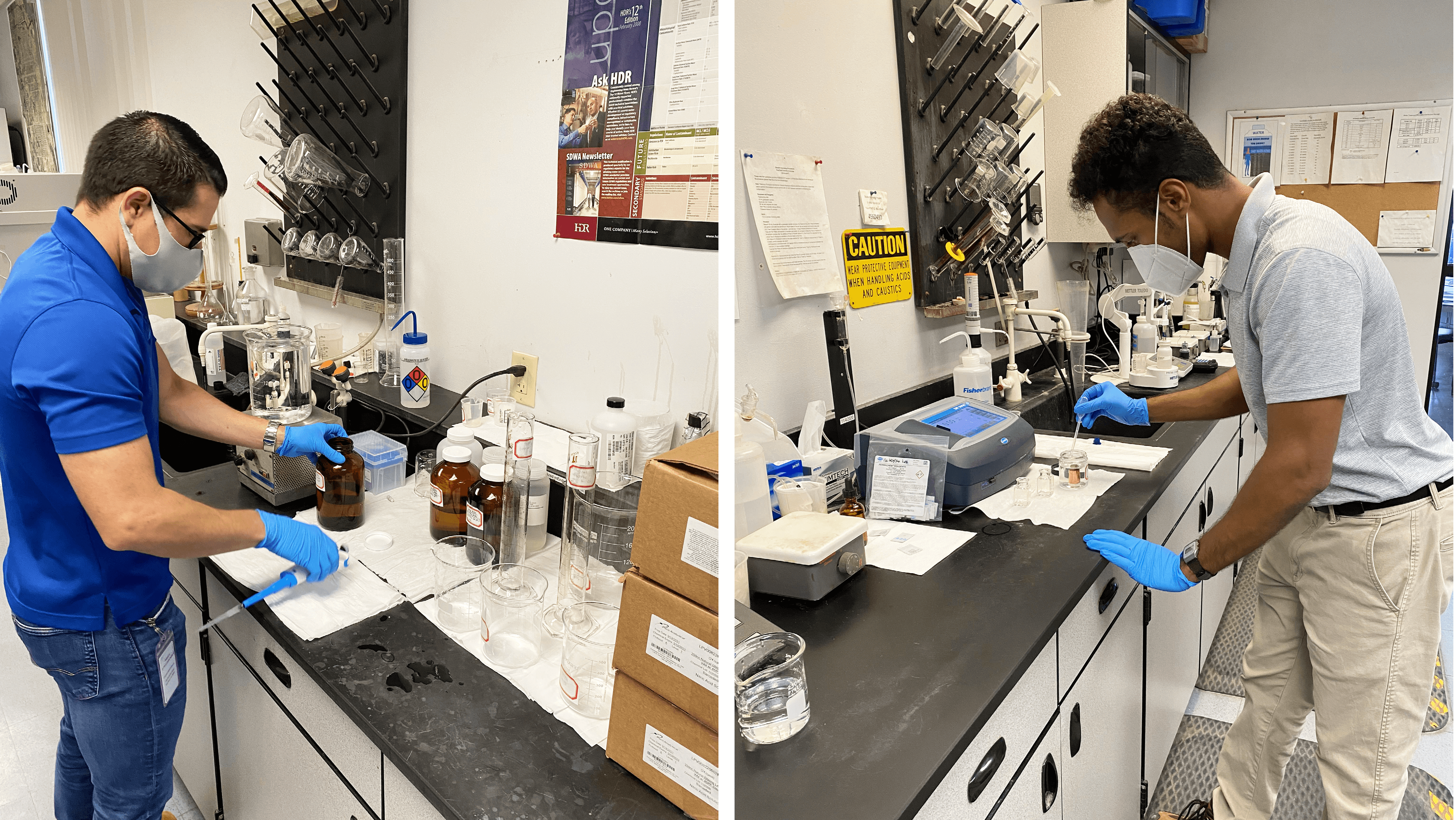

A desktop corrosion control evaluation for existing and future WTP operations was performed, followed by bench-scale immersion jar testing of lead and copper samples for relative corrosion potential. The immersion jar testing involved eight test water conditions comprised of different process blends and corrosion inhibitor formulations, chemically adjusted to match the WTP’s post treatment water quality. Each test water condition contained 10 125-mL glass jars housing lead and copper samples. The Jars were filled with conditioned test water and left stagnant in one-week intervals for 12 weeks. Each week, stagnant test water in the jars was collected for lead and copper analysis by Globaltech. The jars were then refilled with new conditioned test water. At the end of the 12 weeks, the data was compiled and analyzed, delineating relative lead and copper corrosion potential between the eight test water conditions.

The result of Globaltech’s lead and copper evaluation provided FPUA with valuable information that assisted in their consideration of future process blend operations.